Market Opportunity

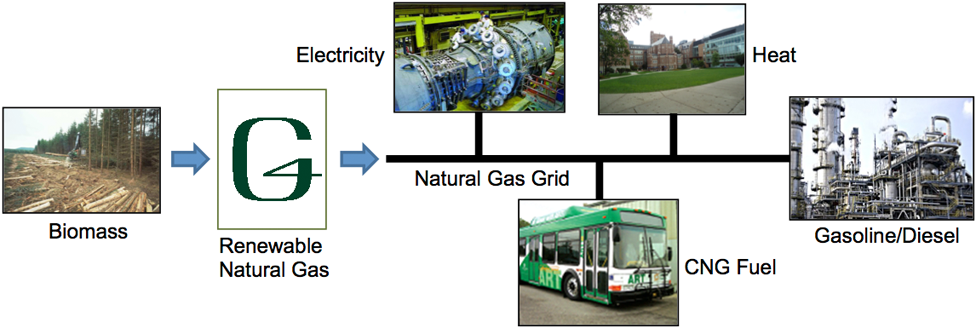

G4's proprietary PyroCatalytic Hydrogenation (PCH) process is a low temperature thermochemical process that enables large scale, economic production of RNG from lignocellulosic biomass. G4 RNG can be produced on a distributed basis in forestry regions and delivered to end users through existing natural gas (NG) pipelines. The G4 RNG can be used in any unmodified natural gas equipment, appliance, vehicle, industrial process, or power generator. The major markets for G4 RNG are renewable natural gas to grid, renewable power generation in existing NG power plants, and low carbon transportation fuels. RNG does not compete with fossil natural gas because fossil NG (including shale gas at record low prices) cannot be used to fulfill the demand for renewable energy. Unlike most other renewable energy vectors, G4 RNG generates and supports significant permanent jobs and local economic development with a small environmental footprint.

Natural gas supplies 23% of the world energy requirements and 33% of NG consumption is for electric power generation. Western Europe and China are consuming more natural gas than available domestically. Consequently, there is a strong global trend towards increasing energy independence and energy security. Climate change is also a global concern and the consumption of fossil natural gas is a significant contributor of greenhouse gas emissions. The G4 PCH technology contributes towards greater energy independence and reduction of greenhouse gases by generating carbon neutral, pipeline grade renewable natural gas using domestically supplied and renewable biomass.

The G4 process exhibits compelling economic value through high energy conversion efficiency and the ability to use low value feedstock. When the gas is used in a combined cycle power generator, the combined conversion efficiency of wood energy to power is over 50% higher than any other biomass to energy technology and the LCOE is 20% lower than wind power.

G4 intends to build two sizes of commercial plant: a large plant with a nominal output of 10,000 GJ/day, and a small plant with an output of 450 GJ/day. Commercial plants consume wood waste (sawdust, slash, thinning, hog fuel), and produce pipeline grade natural gas with 98+% methane content. The plant delivers compressed methane directly into a local or transport natural gas line or compressor station.

Small Commercial Plant (450 GJ/day):

- Requires 36 BDT/day of wood material, about 2 logging trucks per day.

- 11 Full time employees for for plant operations and 8 for biomass collection

- Plot plan for plant is 10m x 15m, with wood handling and storage yard extra (1-3 acres)

Large Commercial Plant (10,000 GJ/day):

- Requires 750 BDT/day of wood material, about 50 logging trucks per day.

- 24 Full time employees for plant operations and 150 for biomass collection

- Plot plan for plant is 75m x 75m, with wood handling and storage yard extra (10-20 acres)

The small commercial unit can be located in areas containing relatively small forest operations such as remote or suburban communities. Abandoned hog fuel piles can also supply the small unit for a number of years. The large commercial units require industrial scale forestry operations to supply enough waste wood to feed the plant. For medium to large sized commercial sawmills in North America and assuming typical forest densities, a harvest area of 40 to 50 km radius will have sufficient forest re-growth to support sawmill operations in a sustainable manner indefinitely.

The G4 RNG process lends itself to production of methane from low cost, excess power generation from intermittent wind and solar power sources. Excess renwable power can be converted into hydrogen which is fed into the G4 RNG process to be converted into RNG for distribution/storage in the natural gas grid. The G4 Power to Gas (P2G) process is a superior alternative to injecting hydrogen into the natural gas grid.