Our Technology

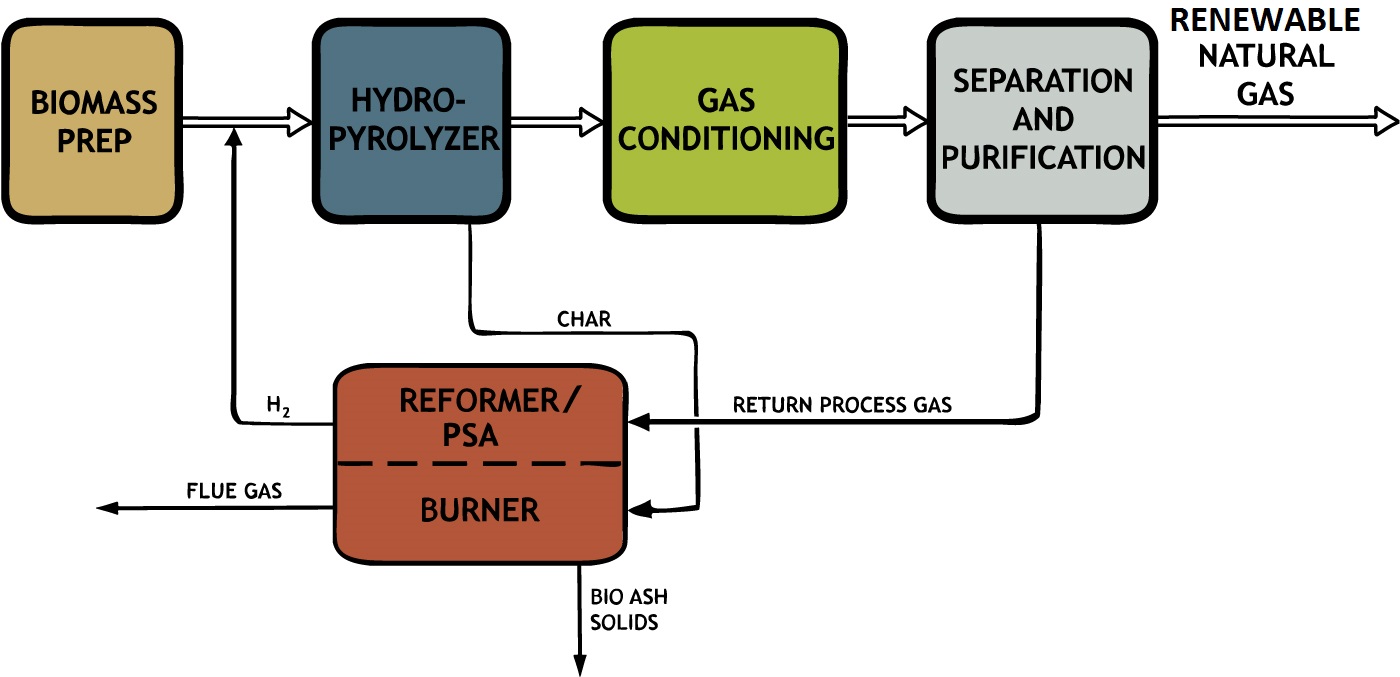

G4 Insight's proprietary process PyroCatalytic Hydrogenation (PCH) uses fast pyrolysis rather than gasification of the biomass to generate a vapor from the solid phase. This fundamental difference enables a low temperature thermochemical process (Figure 1) consisting of the following components:

- Biomass Preparation – Forest biomass is prepared by cleaning, comminution, and partial drying.

- Hydropyrolysis – Biomass is vaporized in a pressurized hydrogen atmosphere by using a recirculating heating media to create a fast pyrolysis process. The generated vapors and aerosols are separated from the solid phase mixture of char and media. The char is further separated from the heating media for use in the reformer.

- Gas Conditioning – The pyrolysis vapors are catalytically converted into methane and steam in the presence of hydrogen gas. This is performed at catalyst temperatures below 650C and minimizes the formation of poly-aromatic hydrocarbons.

- Separation and Purification – the hot gases are cooled in a controlled process and the methane gas is separated and purified from the liquids and remaining hydrogen.

- Hydrogen Generation – A portion of the methane, water, and excess hydrogen is recirculated into a steam methane reformer to generate the hydrogen required for the hydropyrolyzer. The heat source for the endothermic reforming process is the combustion of the char generated in the pyrolysis process.

Forestry biomass composition may be generally represented as C6H9O4. The hydropyrolysis process vaporizes the biomass into volatile gases and aerosols. Tar formation is eliminated through G4 proprietary processes. Catalytic formation of methane involves a variety of reactions which hydrogenate the pyrolysis gases to form methane and water:

C6H9O4 + 11.5 H2 → 6 CH4 + 4 H2O

However, hydropyrolysis always produces a portion of solid char so that not all of the carbon is transferred from wood to methane. The G4 process utilizes this char to generate the heat required for making hydrogen with the reformer. No external hydrogen supply is required in the PCH process. The thermal energy of the reformer heating and process streams are utilized to energize the heating media used in the pyrolysis process and the biomass drying. Separation and purification of a high grade methane mixture is performed by a proprietary pressure swing adsorption process and yields methane purity levels over 98%.

Net energy conversion efficiency (HHV basis) from biomass to methane is nominally greater than 70%. The G4 RNG product will meet all natural gas pipeline specifications around the world. The gas is renewable and sustainable, suitable for renewable power generation and can be classified as a Super-Ultra-Low-Carbon transportation fuel (California).

G4 has multiple patents issued in the US, EU, UK, Canada, and China.

The G4 technology development phase and has achieved 88% to 100% of commercial target performance for core processes.